6 - Trowal room

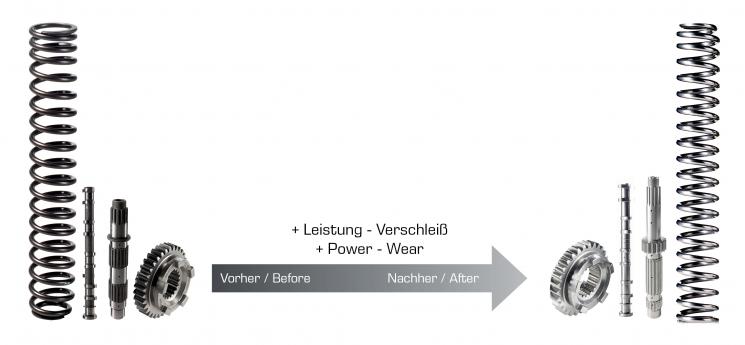

The grinding and compacting results in low friction of all components as well as a very homogeneous surface of the treated parts.

This results in a better running characteristic of the telescopic fork due to the treated fork spring. There is no metallic residue that attacks the guides. The chrome-plated surface of the sliding tubes are protected. The interval of fork oil change or sealing is considerably delayed. The treatment of the components protects all gear parts and guides in the engine. There is hardly any wear! A considerably better shifting is the result of the fine grinding process. The treatment time of the gearbox is 10 hours and that of the fork springs is 6 hours.

Trowalising is a fine grinding process invented by the Solingen entrepreneur Walther Trowal. A suitable grinding wheel together with an emulsion in a trough vibrator provides a relative movement.